How to Manufacture Outdoor Enclosures: A Comprehensive Guide

How to Manufacture Outdoor Enclosures: A Comprehensive Guide

Feb 13 , 2025Outdoor enclosures are essential for protecting sensitive equipment, electronics, and machinery from environmental factors such as rain, dust, UV radiation, and extreme temperatures. These enclosures are widely used in industries like telecommunications, energy, automotive, and industrial automation.

Manufacturing outdoor enclosures requires careful planning, material selection, and precision engineering to ensure durability, functionality, and compliance with industry standards. In this blog, we'll walk you through the key steps involved in manufacturing outdoor enclosures.

1. Define the Requirements

Before starting the manufacturing process, it’s crucial to define the specific requirements of the outdoor enclosure. Consider the following factors:

-

Purpose: What equipment will the enclosure house? (e.g., electrical components, servers, sensors)

-

Environmental Conditions: Will it be exposed to rain, snow, UV rays, or corrosive substances?

-

Size and Dimensions: What are the space requirements for the equipment and additional components like cables or cooling systems?

-

Regulatory Standards: Does the enclosure need to meet specific certifications (e.g., IP rating, NEMA standards)?

2. Choose the Right Materials

The material selection is critical for ensuring the enclosure’s durability and performance. Common materials used for outdoor enclosures include:

-

Stainless Steel: Offers excellent corrosion resistance and strength, making it ideal for harsh environments.

-

Aluminum: Lightweight, corrosion-resistant, and easy to fabricate. It’s also a good choice for thermal management.

-

Polycarbonate or ABS Plastic: Provides good impact resistance and is suitable for lightweight enclosures.

-

Galvanized Steel: A cost-effective option with moderate corrosion resistance.

The choice of material depends on the environmental conditions, budget, and specific application requirements.

3. Design the Enclosure

The design phase involves creating detailed drawings and 3D models of the enclosure. Key design considerations include:

-

Structural Integrity: Ensure the enclosure can withstand physical impacts, wind loads, and other stresses.

-

Thermal Management: Incorporate ventilation, fans, or cooling systems to prevent overheating of internal components.

-

Sealing and Gaskets: Use high-quality gaskets and seals to achieve the desired IP rating (e.g., IP65 for dust-tight and water-resistant enclosures).

-

Accessibility: Include doors, panels, or hinges for easy access to the equipment inside.

-

Aesthetic Appeal: Consider the enclosure’s appearance, especially if it will be installed in visible locations.

Advanced CAD software is often used to create precise designs and simulate the enclosure’s performance under various conditions.

4. Fabricate the Enclosure

Once the design is finalized, the fabrication process begins. The steps typically include:

a. Cutting and Forming

-

Use laser cutting, plasma cutting, or shearing machines to cut the material into the required shapes.

-

Bend and form the material using press brakes or roll-forming machines to create the enclosure’s structure.

b. Welding and Joining

-

Weld the components together for a sturdy and seamless structure. TIG welding is commonly used for stainless steel and aluminum.

-

For plastic enclosures, use ultrasonic welding or adhesive bonding.

c. Surface Treatment

-

Apply surface treatments to enhance durability and aesthetics. Common treatments include:

-

Powder coating for corrosion resistance and color customization.

-

Anodizing for aluminum enclosures to improve hardness and corrosion resistance.

-

Galvanizing for steel enclosures to prevent rust.

-

d. Assembly

-

Install hinges, locks, handles, and other hardware.

-

Add internal mounting panels, cable management systems, and other accessories as needed.

5. Test the Enclosure

Before the enclosure is ready for use, it must undergo rigorous testing to ensure it meets the required standards. Common tests include:

-

IP Rating Testing: Verify the enclosure’s resistance to dust and water ingress.

-

Impact Testing: Assess the enclosure’s ability to withstand physical impacts.

-

Thermal Testing: Ensure the enclosure can maintain safe operating temperatures for the equipment inside.

-

UV Resistance Testing: For plastic enclosures, test their resistance to UV degradation.

6. Quality Control and Certification

Quality control is a critical step in the manufacturing process. Inspect the enclosure for defects, ensure all components are properly installed, and verify compliance with industry standards. Obtain necessary certifications (e.g., UL, CE, RoHS) to demonstrate the enclosure’s quality and safety.

7. Packaging and Delivery

Once the enclosure passes all tests and inspections, it’s ready for packaging and delivery. Use protective packaging materials to prevent damage during transit. Include user manuals, installation guides, and warranty information with the product.

Key Considerations for Manufacturing Outdoor Enclosures

-

Customization: Many customers require custom enclosures tailored to their specific needs. Offer flexible design and fabrication options.

-

Sustainability: Use eco-friendly materials and processes to reduce the environmental impact of manufacturing.

-

Cost Efficiency: Optimize the design and production process to minimize costs without compromising quality.

Manufacturing outdoor enclosures is a complex but rewarding process that requires expertise in design, engineering, and material science. By following the steps outlined above, you can produce high-quality enclosures that meet the demands of various industries and environments.

Whether you're a manufacturer or a business looking for outdoor enclosures, understanding the process can help you make informed decisions and ensure the success of your projects.

If you have any questions or need assistance with your outdoor enclosure needs, feel free to reach out to our team of experts!

AZE Telecom: Empowering Connectivity with Innovative Solutions

In today's fast-paced, hyper-connected world, reliable and efficient telecommunications infrastructure is the backbone of modern society. From enabling seamless communication to supporting the growth of smart cities and IoT (Internet of Things), the telecom industry plays a pivotal role in shaping the future. At the forefront of this transformation is AZE Telecom, a trusted name in the telecommunications sector known for its innovative solutions, high-quality products, and customer-centric approach.

Who is AZE Telecom?

AZE Telecom is a leading provider of telecommunications solutions, specializing in the design, manufacturing, and distribution of high-performance products and systems. With years of experience and a commitment to excellence, AZE Telecom serves a diverse range of industries, including:

-

Telecommunications service providers

-

Data centers

-

Industrial automation

-

Smart infrastructure

-

Renewable energy

The company’s mission is to deliver cutting-edge solutions that enhance connectivity, improve operational efficiency, and support the evolving needs of the digital age.

Core Offerings of AZE Telecom

AZE Telecom offers a comprehensive portfolio of products and services designed to meet the demands of modern telecommunications networks. Key offerings include:

1. Outdoor Enclosures and Cabinets

AZE Telecom specializes in manufacturing robust outdoor enclosures and cabinets that protect sensitive telecommunications equipment from harsh environmental conditions. These enclosures are designed to meet international standards (e.g., IP65, NEMA 4X) and are widely used for housing fiber optic systems, power supplies, and networking equipment.

2. Fiber Optic Solutions

As fiber optic networks continue to expand, AZE Telecom provides a range of fiber optic products, including distribution panels, splice closures, and cable management systems. These solutions ensure high-speed data transmission and reliable connectivity.

3. Power Distribution Systems

AZE Telecom offers advanced power distribution units (PDUs) and backup power solutions to ensure uninterrupted operation of telecom infrastructure. These systems are designed for efficiency, scalability, and ease of maintenance.

4. Customized Solutions

Understanding that every project has unique requirements, AZE Telecom provides customized solutions tailored to specific needs. From design to delivery, the company works closely with clients to develop products that meet their exact specifications.

What Sets AZE Telecom Apart?

1. Commitment to Quality

AZE Telecom is dedicated to delivering products of the highest quality. The company adheres to stringent quality control processes and complies with international standards, ensuring that every product meets or exceeds customer expectations.

2. Innovation and R&D

Innovation is at the heart of AZE Telecom’s operations. The company invests heavily in research and development to stay ahead of industry trends and deliver state-of-the-art solutions.

3. Customer-Centric Approach

AZE Telecom places a strong emphasis on building long-term relationships with its customers. By offering personalized service, technical support, and timely delivery, the company has earned a reputation for reliability and trustworthiness.

4. Global Reach

With a strong presence in international markets, AZE Telecom serves clients across the globe. The company' extensive distribution network ensures that its products are readily available wherever they are needed.

AZE Telecom's Impact on the Industry

AZE Telecom has played a significant role in advancing telecommunications infrastructure worldwide. Some of its key contributions include:

-

Supporting the rollout of 5G networks by providing durable and scalable enclosures and power solutions.

-

Enabling the expansion of fiber optic networks in urban and rural areas.

-

Helping industries transition to smart technologies by providing reliable connectivity solutions.

Why Choose AZE Telecom?

Whether you’re a telecom operator, a system integrator, or an industrial enterprise, AZE Telecom is your trusted partner for all your connectivity needs. Here’s why customers choose AZE Telecom:

-

Proven Expertise: Decades of experience in the telecommunications industry.

-

Comprehensive Product Range: A wide array of solutions to meet diverse requirements.

-

Competitive Pricing: High-quality products at cost-effective prices.

-

Sustainability: Eco-friendly manufacturing processes and products.

Looking Ahead

As the world becomes increasingly connected, the demand for innovative telecommunications solutions will continue to grow. AZE Telecom is committed to staying at the forefront of this evolution, leveraging its expertise and resources to empower connectivity and drive progress.

Whether it's building the infrastructure for 5G networks, supporting the growth of IoT, or enabling smart city initiatives, AZE Telecom is dedicated to shaping a connected future.

Get in Touch with AZE Telecom

If you're looking for reliable, high-quality telecommunications solutions, AZE Telecom is here to help. Visit our website or contact our team to learn more about our products and services. Let’s work together to build a smarter, more connected world.

Looking for NEMA Type outdoor enclosures?

Outdoor Server Cabinet Wall Mount Outdoor Cabinet Outdoor Telecom Enclosure Outdoor Battery Enclosure

From data center to outdoor telecom infrastructure products, AZE has the right product for you. AZE designs and manufactures Server Racks and Enclosures, Outdoor Telecom Cabinets and Electronic Enclosures, Power Distribution (Basic Rack PDUs and Smart PDUs), KVM Switches and Fiber optics products to globe customers in the market.

Make IT Connected, AZE can support you to make IT happen with affordable cost.

Contact AZE to customize your IP rated outdoor enclosures.

Related Products

Related Article

KVM Switches Frequently Asked Questions

Frequently Asked Questions for the KVM switches

Server Rack Enclosure Cabinet Buying Guide

How to select a right server rack cabinet enclosure

What is IP55 Outdoor waterproof Enclosure

What is IP55 Outdoor waterproof or weatherproof electrical Enclosure?

NEMA Outdoor Telecom Enclosures Solutions

NEMA 4,NEMA 4 Rated Outdoor Telecom Enclosures Solutions Provider

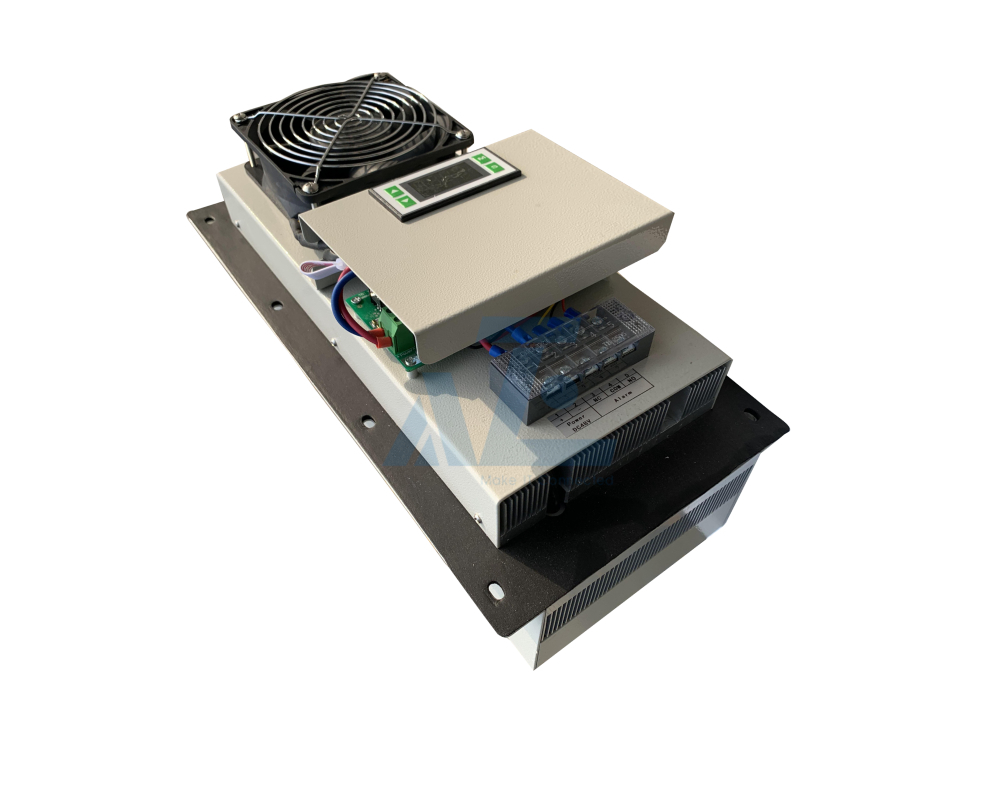

Outdoor Cabinet Enclosure Air Conditioner

Outdoor cabinet air conditioners keep your equipment cool outside

NEMA Outdoor Enclosure Ratings-Type 3R,4,4X

AZE manufactures NEMA 4,NEMA 4 Rated electrical outdoor enclosures